This is one in a series of briefs prepared as part of C2ES’s Climate Innovation 2050 initiative, which brings together leading companies to examine potential pathways toward substantially decarbonizing the U.S. economy. Other briefs focus on Agriculture & Forestry, Buildings, Oil & Gas, Power Generation, and Transportation. (Note: Full citations to supporting materials can be found in the pdf version of this brief.)

This brief provides an overview of emissions trends and projections, and of decarbonization challenges and opportunities, in the industrial sector. Key points include:

The industrial sector encompasses a wide range of sub-sectors including manufacturing (e.g., steel, cement, chemicals), mining, and construction. Manufacturing, construction and non-oil and gas mining contributed more than $3 trillion in GDP in 2016 and employed nearly 20 million people.

The United States’ five largest energy-consuming industries—bulk chemicals, oil and gas, steel, paper, and food products—account for 56.5 percent of industrial energy use, but only 20.8 percent of product value. Other energy-intensive industries include glass, cement, and aluminum.

Industrial sector emissions have been declining since the mid-1990s, driven by the adoption of new, less carbon-intensive processes, fuel switching (e.g., coal to natural gas and renewables), increased efficiency, a shift in metal production to other countries, and the United States’ continued transition from a manufacturing to a more service-oriented economy and from more energy-intensive to less energy-intensive industries.

In general, energy-intensive industries are growing more slowly in the United States than industries with lower energy intensities. However, sustained investments in the U.S. chemicals industry are expected to continue the strong growth in domestic bulk chemical production.

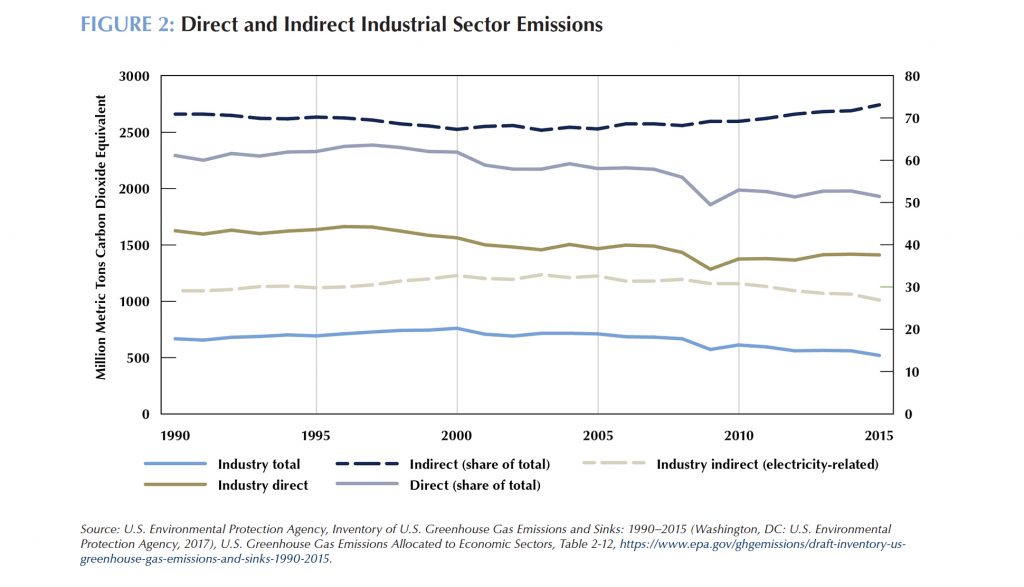

In 2015, direct emissions from the industrial sector represented 21.4 percent of total U.S. greenhouse gas emissions. Direct emissions come from diverse sources and accounted for roughly three-quarters of the sector’s total emissions. On-site combustion of fossil fuels for heat and power made up 53.7 percent of the sector’s direct emissions for 2015, while various industrial processes were responsible for 16.6 percent . Direct emissions from industry make the sector the third-largest source of greenhouse gases (after transportation and electric power) in the United States.

Indirect emission from the use of electricity generated off-site account for the rest of the sector’s emissions. Including its direct and indirect emissions, industry is the largest greenhouse gas-emitting sector in the United States, accounting for nearly 30 percent of total U.S. emissions.

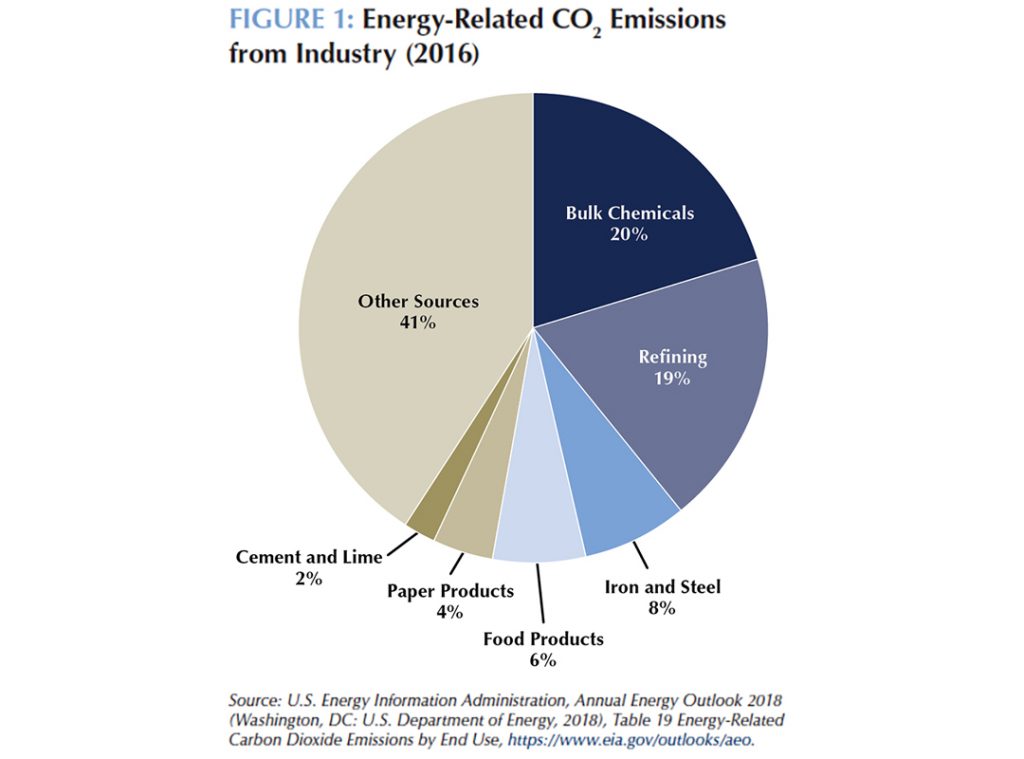

Sub-sector emissions profiles vary widely. According to the Energy Information Administration’s (EIA) 2018 Annual Energy Outlook (AEO), bulk chemicals, refining and iron and steel production were the three largest sources of energy-related carbon dioxide emissions, which account for around three-quarters of the sector’s total (direct and indirect) emissions (Figure 1).

In addition to CO2, industry accounts for 25 percent of total U.S. non-CO2 greenhouse gas emissions, including 41 percent of methane, 7 percent of nitrous oxide, and 20 percent of other greenhouse gas (e.g., hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), and sulfur hexafluoride) emissions.

From 1996 to 2015, industry emissions declined about 18.7 percent, including a 15.1 percent decline in direct emissions and a 27 percent decline in indirect emissions from off-site electricity) as shown in Figure 2. While total emissions have been fairly flat since 2010, the share of direct emissions has been increasing.

From 1990 to 2015, direct emissions from industrial processes and product use increased by about 10.5 percent, driven primarily by a 270 percent increase in emissions of HFCs, which are substitutes for ozone-depleting substances. Emissions from cement production increased 19.1 percent during this period due to increased production, primarily driven by increased construction activity. Emissions have also increased in semiconductor manufacturing, titanium dioxide production, and petrochemical production.

From 1990 to 2015, direct emissions from industrial processes and product use increased by about 10.5 percent, driven primarily by a 270 percent increase in emissions of HFCs, which are substitutes for ozone-depleting substances. Emissions from cement production increased 19.1 percent during this period due to increased production, primarily driven by increased construction activity. Emissions have also increased in semiconductor manufacturing, titanium dioxide production, and petrochemical production.

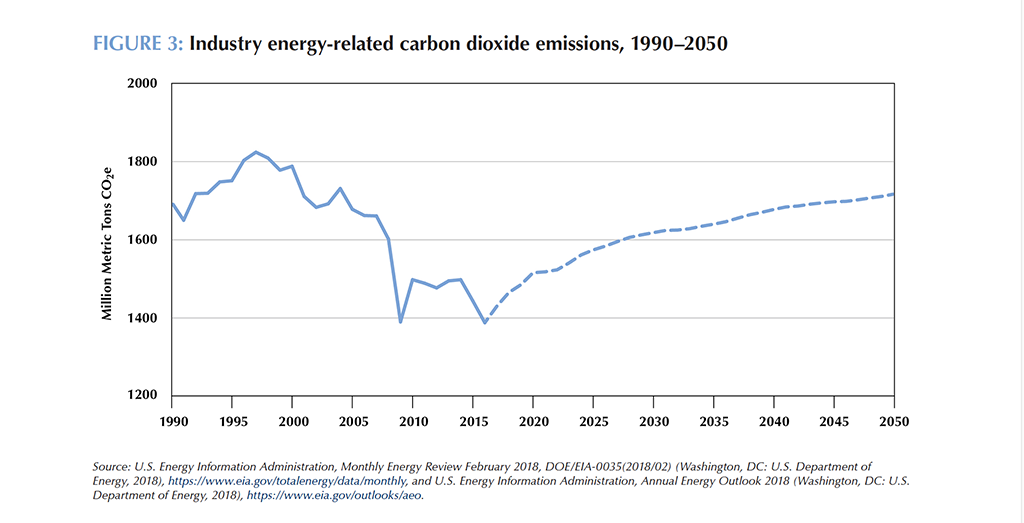

Projections of future emissions focus primarily on energy-related CO2, which currently represents roughly three-quarters of total industry emissions. The EIA projects total delivered energy consumption in the industrial sector will grow about 33.7 percent from 2017 to 2050, driven primarily by economic growth and relatively low energy prices.

Having fallen through 2010, and remained flat through 2015, the sector’s energy-related CO2 emissions are now projected to increase 17.6 percent through mid-century, fueled by low prices for energy, particularly natural gas and natural gas liquids (Figure 3). The six largest sources of manufacturing emissions are expected to continue to be bulk chemicals, refining, iron and steel, food products, paper products, and cement and lime production. In absolute terms, emissions from bulk chemical manufacturing are forecast to increase the most, 126.7 MMtCO2 or 45 percent. Other manufacturing areas expected to see increases are food products (41.4 percent), fabricated metal products (37.1 percent), plastics (27.8 percent), aluminum (23.9 percent), and transportation equipment (20.3 percent). These six categories account for 60 percent of projected increases in energy-related CO2 emissions from industry.

Decarbonizing the industrial sector is generally considered more technically challenging than in the building and transportation sectors, as it concerns emissions not only from heat and power but also from products and processes. Potential pathways toward substantially reducing the sector’s emissions include: improved energy efficiency; fuel switching; carbon capture, utilization, and storage (CCUS); and process changes.

Improving the efficiency of heating and motors will be particularly important because they account for about 30 percent of total industry energy use and could yield benefits across diverse sub-sectors.

The emergence of the “internet of things” (e.g., embedding digital technologies within industrial machinery) has created new opportunities for intelligent efficiency and automation, which can further reduce industrial-scale resource and fuel consumption and emissions. One recent study found that intelligent efficiency could reduce global CO2 emissions 20 percent by 2030, with about 22 percent of that reduction potential in the manufacturing sector.

Combined heat and power (CHP) systems have helped reduce energy use across industrial sectors (e.g., bulk chemicals, pulp paper, petroleum and coal). Separate centralized electricity generation and on-site heat generation have a combined efficiency of around 45 percent, whereas CHP systems can reach efficiency levels of 80 percent. However, adoption of CHP systems has stalled in recent years due to high capital costs, technical complexity, and policy changes.

Increased electrification of the industrial sector will reduce emissions. Since on-site fossil fuel combustion is the largest direct source of emissions, steps to reduce these emissions, including electrification and the use of (decarbonized) pipeline gas, offer perhaps the biggest reduction potential. While industrial electric technologies (e.g., electric boilers and electric technologies for process heat) already exist, they are only used in a subset of industrial sectors. Challenges in decarbonizing via electrification include large capital investments for equipment, the high relative cost of electricity vs. fossil fuels, and technical hurdles associated with electrifying energy-intensive and high-temperature processes.

Industrial carbon capture, utilization, and storage (CCUS) can play an important role in reducing emissions in subsectors. CCUS technologies can be applied to steel, cement, chemicals, fertilizer production plants, hydrogen and refining. Experience with early CCUS projects like the Archer Daniels Midland Illinois Industrial Carbon Capture and Storage project—the world’s first commercial-scale ethanol plant retrofitted with carbon capture—could help lower the cost of future CCUS projects. Recently adopted federal tax credits for CCUS will help deploy some projects. However, more targeted, industry-specific support is likely needed for research, development, demonstration, and deployment, as well as support for private sector commercialization.

For specific industries, process improvements can reduce energy needs and, therefore, greenhouse gas emissions. For example, shifting from basic oxygen blast furnaces to electric arc furnaces in the production of iron-ore steel contributed to a 37 percent reduction in the energy intensity of U.S. crude steel production from 1991–2010. In some cases, switching inputs or raw materials can reduce emissions—for instance, using fly ash from coal-fired power plants instead of carbon-intensive clinker in cement production. Other process changes and substitutions can reduce emissions of non-CO2 gases with high global warming potential.

Crooks, Ed, “Investment in US chemicals industry rises,” Financial Times, June 14, 2015, https://www.ft.com/content/5c969680-12b1-11e5-8cd7-00144feabdc0.

“ExxonMobil to Build 13 New Chemicals Facilities,” Powder & Bulk Solids, March 7, 2018, http://www.powderbulksolids.com/news/ExxonMobil-to-Build-13-New-Chemicals-Facilities-by-2025-03-07-2018.

Global e-Sustainability Initiative, 2015,SMARTer2030, http://smarter2030.gesi.org/downloads/Full_report.pdf.

International Energy Agency, 2015, Carbon Capture and Storage: The solution for deep emissions reductions, https://www.iea.org/publications/freepublications/publication/carbon-capture-and-storagethe-solution-for-deep-emissions-reductions.html.

Schipper, Mark and Douglas, Joel, “Industrial onsite electricity concentrated in chemicals, oil, and paper manufacturing,” Today in Energy, May 20, 2014, https://www.eia.gov/todayinenergy/detail.php?id=16351.

Perl, Kelly, “Changes in steel production reduce energy intensity,” Today in Energy, July 29, 2016, https://www.eia.gov/todayinenergy/detail.php?id=27292.

U.S. Energy Information Administration, 2016, Monthly Energy Review, https://www.eia.gov/totalenergy/data/monthly.

U.S. Energy Information Administration, 2018, Annual Energy Outlook 2018, https://www.eia.gov/outlooks/aeo.

U.S. Environmental Protection Agency, 2017, Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2015, https://www.epa.gov/ghgemissions/draft-inventory-us-greenhouse-gas-emissions-and-sinks-1990-2015.