Testimony of

Bob Perciasepe

President, Center for Climate and Energy Solutions (C2ES)

Before the

House Energy and Commerce Committee and

Subcommittee on Environment and Climate Change

September 18, 2019

Good morning, I am Bob Perciasepe, the president of the Center for Climate and Energy Solutions (C2ES). Before joining C2ES, I was most recently the Deputy Administrator of the U.S. Environmental Protection Agency (EPA) from 2009 through 2014. Before that I was the chief operating officer for the National Audubon Society and the Secretary of Maryland’s Department of Environment. A full biography is attached and submitted for the record.

The organization I now lead, C2ES, is the successor to the Pew Center on Global Climate Change, which was founded in 1998 and is widely recognized as an influential and pragmatic voice on climate issues. Our mission is to advance strong policy and action to reduce greenhouse gas emissions, promote clean energy, and strengthen resilience to climate impacts. A key objective is a national market-based program to reduce emissions cost-effectively. We believe a sound climate strategy is essential to ensure a strong, sustainable economy.

C2ES has long believed that business engagement is critical for developing efficient, effective solutions to the climate problem. Our Business Environment Leadership Council (BELC), established at our founding with 13 companies, has now grown to three dozen mostly Fortune 500 companies across a wide range of sectors. While individual companies hold their own views on policy specifics, they are united with C2ES in the belief that voluntary action alone will not be enough to address the climate challenge. BELC members subscribe to the following guiding principles:

- We accept the scientific consensus that climate change is occurring and that the impacts are already being felt. Delaying action will increase both the risks and the costs.

- Businesses can and should incorporate responses to climate change into their core corporate strategies by taking concrete steps in the U.S. and abroad to establish and meet greenhouse gas (GHG) emission reduction targets, and/or invest in low and zero GHG products, practices and technologies.

- The United States should significantly reduce its GHG emissions through economy-wide, mandatory approaches, which may vary by economic sector and include a flexible, market-based program. Complementary policies may also be necessary for sectors such as buildings, electricity generation, forestry, agriculture, and transportation that will help drive innovation and ease the transition to a low-carbon economy.

- Climate change is a global challenge that ultimately requires a global solution. An international climate framework must establish fair, effective, and binding commitments for all developed and major developing economies.

We are grateful for the valuable contributions that BELC members provide to our work. C2ES, however, is solely responsible for its positions, programs, and publications.

Climate Innovation 2050

For the past 18 months, C2ES has convened more than two dozen BELC members and other leading companies to examine potential pathways toward substantially decarbonizing the U.S. economy.[1] Sectors represented include power, transportation, finance, tech, oil and gas, chemicals, cement, steel, manufacturing, and food/agriculture.

To date, Climate Innovation 2050 has produced:

(1) Background briefs examining key challenges and opportunities in decarbonizing U.S. agriculture/land use, buildings, electric power, industry, oil and gas, and transportation;

(2) A set of near-term federal actions that we believe could garner bipartisan support and strengthen the foundation for comprehensive long-term solutions; and

(3) A report, Pathways to 2050: Scenarios for Decarbonizing the U.S. Economy, that presents and draws insights from three alternative scenarios for decarbonizing the U.S. economy.

C2ES is now working with participating companies to develop a comprehensive strategy outlining the key policies and actions needed over the coming decade to put the United States on the path to carbon neutrality by mid-century. We plan to release this decarbonization strategy this fall.

Decarbonizing the Economy and the Industrial Sector

Decarbonizing the U.S. economy is a formidable task. The latest science underscores the imperative of achieving carbon neutrality – a net balance of greenhouse gas emissions to, and withdrawals from, the atmosphere – by 2050. To date, the U.S. reduced its net emissions by 13 percent below 2005 levels.[2] That leaves a significant margin yet to account for.

Pathways to deep decarbonization generally focus on three, equally important activities: (1) end-use fuel switching, primarily to electric sources (e.g., switching from gasoline- and diesel-powered to electric vehicles), (2) decarbonization of the electric power sector, and (3) increasing deployment of energy efficiency (Figure 1).[3] All three strategies are relevant to decarbonizing the industrial sector.

Figure 1: Three Pillars of a Clean Energy Economy

Source: Risky Business Project, From Risk to Return: Investing in a Clean Energy Economy, 2016.

According to the Environmental Protection Agency’s most recent Inventory of Greenhouse Gases, the industrial sector’s greenhouse gas emissions, including both direct emissions and indirect emissions (i.e., from offsite electricity), totaled 915 million metric tons in 2017, or 29.7 percent of total U.S emissions. The bulk of these emissions are from the combustion of fossil fuels to generate energy (i.e., electricity and heat) used in manufacturing processes. Industrial process and product use emissions were nearly 359 million metric tons carbon dioxide equivalent (MMtCO2) in 2017 or 5.6 percent of total U.S. emissions.

U.S. industrial sector emissions have been declining since the mid-1990s. Contributing factors include the adoption of less carbon-intensive manufacturing processes, fuel switching (e.g., coal to natural gas and renewables), increased energy efficiency, a shift in metal production to other countries, and the broader transition to a more service-oriented U.S. economy.

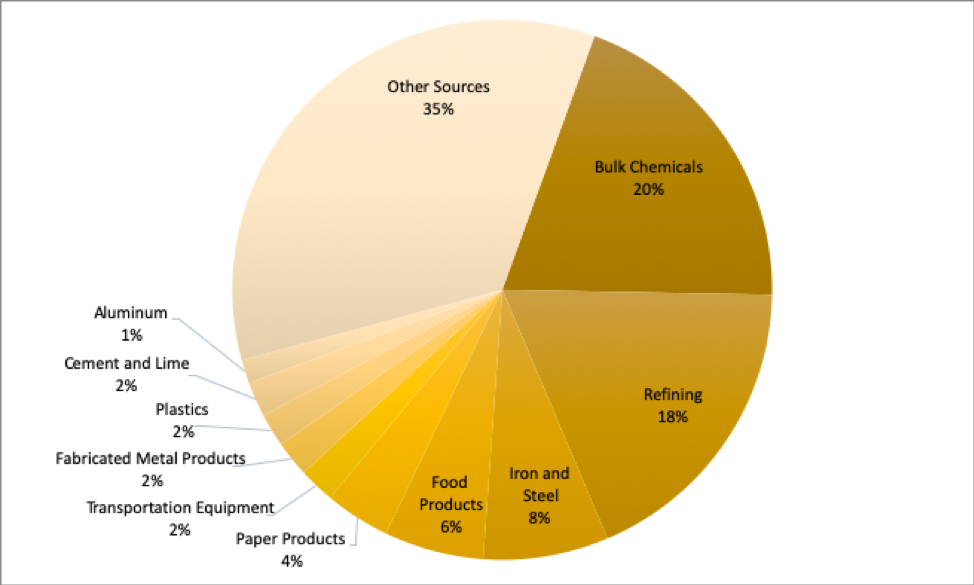

Having fallen through 2010, and remained flat through 2015, the sector’s energy-related carbon dioxide (CO2) emissions are now projected to increase 17.6 percent through mid-century, fueled by low prices for energy, particularly natural gas and natural gas liquids.[4], [5] The six largest sources of manufacturing emissions are expected to continue to be bulk chemicals, refining, iron and steel, food products, paper products, and cement and lime production. In absolute terms, emissions from bulk chemical manufacturing are forecast to increase the most, 126.7 MMtCO2 or 45 percent. Other manufacturing areas expected to see increases are food products (41.4 percent), fabricated metal products (37.1 percent), plastics (27.8 percent), aluminum (23.9 percent), and transportation equipment (20.3 percent). These six categories account for 60 percent of projected increases in energy-related CO2 emissions from U.S. industry.

Given its tremendous diversity, its heavy reliance on large quantities of thermal heat, and the fundamental nature of many core manufacturing process, the industrial sector is especially challenging to decarbonize. Just 10 of the 100-plus industrial sub-sectors account for two-thirds of the sector’s energy-related CO2 emissions (Figure 2). The largest source of this energy demand is heat for industrial processes. Metal, glass, and cement making, for instance, demand temperatures in excess of 2,000 degrees F. Generating this heat with sources other than conventional fossil fuel combustion is challenging, particularly at the higher temperature range.

Figure 2: Energy-Related CO2 Emissions from Industry (2017)

Source: U.S Energy Information Administration, Annual Energy Outlook 2019

Apart from the technical challenges, the industrial sector faces unique economic pressures. For energy-intensive subsectors producing globally traded products, the incremental costs of mitigating emissions may pose a competitive disadvantage if competitors in other countries do not face similar costs. Moreover, global companies with facilities (i.e., large and small) in remote geographies add to this challenge. Often, these facilities are the largest local employer and they contribute substantially to the local tax base. Also, relatively recent long-lived investments in on-site natural gas-fired generation and conversions from coal- to natural gas boilers may lock in emissions for the economic life of those assets.

Given the many challenges to eliminating industrial sector process emissions, two additional strategies will be vital in the long term to achieve carbon neutrality economy-wide. The first is the use of carbon capture technologies to capture industrial CO2 emissions for storage or for use in commercial products. The second is the generation of “negative emissions” outside the sector – through land-based sequestration and direct air capture technologies – to offset the industrial sectors’ remaining emissions.

However, much can and is being done right now to reduce the sector’s emissions. As I will highlight, solutions are emerging, and many companies are investing in them.

Innovative Actions by Companies

A large number of actions by companies shows that U.S. industry takes climate change seriously, can continue to be a global leader, as well as maintain competitiveness.

Key Technologies

Some technological emission reduction solutions are applicable across multiple industry sub-sectors while others apply only to specific sub-sectors. Cross-sub-sector solutions include implementation of energy efficiency strategies, greater use of combined heat and power (CHP) systems, adoption of carbon capture utilization and storage (CCUS) for process emissions and on-site power generation, and fossil fuel switching. Emission reductions that derive from developing and deploying new, lower- and non-emitting industrial processes as well as incorporating CCUS into those processes are largely limited to individual sub-sectors.

CCUS is currently in use at-scale (i.e., capturing at least 1 million tons of carbon dioxide per year) at two industrial plants in the United States: Air Products’ hydrogen production facility in Texas and Archer Daniels Midland’s ethanol production facility in Illinois.[6] Supportive tax credits for CCUS enacted last year under 45Q are expected to significantly increase deployment in the United States. Modeling by the Clean Air Task Force suggests that the 45Q tax credit could provide incentives to capture up to 49 million metric tons in the electricity sector alone. The tax credits, however, can also be claimed by CCUS projects outside the power sector, such as CCUS on ethanol facilities, oil refineries, cement and steel manufacturing plants. To deeply decarbonize the industrial sector, significantly higher deployments will be required over the next three decades.

Multi-Sub-Sector technologies

Improving the efficiency of heating (e.g., better insulation) and equipment (e.g., motors) could yield significant benefits across diverse sub-sectors. Additionally, imbedding digital technologies within industrial machinery creates new opportunities for intelligent efficiency and automation, which can further reduce industrial-scale resource and fuel consumption and emissions. Also, greater use of recycling, particularly in the metals and pulp and paper subsectors can reduce energy consumption thereby reducing emissions.

CHP systems have helped reduce energy use across industrial sectors (e.g., bulk chemicals, pulp and paper, petroleum and coal). Separate centralized electricity generation and on-site heat generation have a combined efficiency of around 45 percent, whereas CHP systems can reach efficiency levels of 80 percent or greater.[7] However, adoption of CHP systems has stalled in recent years due to high capital costs, technical complexity, and policy changes. According to DOE statistics, there is more than 80 GW of CHP deployed, and there is the technical potential to install more than 240 GW of CHP across the U.S.[8], [9], [10]

While deploying CHP systems at industrial facilities can deliver significant emission reductions, ultimately all carbon emissions must be avoided. Logically, this will require eventually retrofitting all existing CHP systems with CCUS technology. In the coming years newly deployed CHP systems could make use of novel technology (or a comparable solution) currently being commercialized by Net Power, which is able to eliminate all air emissions after combusting natural gas in a pure oxygen environment.[11]

An additional decarbonization strategy is fuel switching. In some instances, this will involve switching from fossil fuels to electricity (e.g., swapping from fossil fuel to electric boilers for heating requirements) or utilizing alternatives for traditional fossil fuels. For example, using captured natural gas from landfills or synthetic natural gas (SNG) from gasified biomass and anaerobic digestion. Additionally, SNG and hydrogen for industrial purposes can be produced from renewables overgeneration.[12] Also, fuel-switching alternatives for CHP include new small and advanced nuclear power plants (particularly molten salt reactors that operate at very high temperatures), which are capable of supplying many sub-industries with the heat and power they require. These latter options must be inherently safe, cost-effective, and have the public’s acceptance.

Single Sub-Sector Technologies

Developing new manufacturing processes that emit fewer greenhouse gases is a key challenge for decarbonizing the industrial sector. Already, improvements are being made in the areas of aluminum, steel, chemicals and cement. And in the bulk chemical space, carbon-free ammonia production may be on the horizon.

As economies continue to grow and develop, aluminum production is expected to expand through mid-century as a lighter weight alternative to steel. In 2015, Apple partnered with Alcoa and Rio Tinto (who formed a joint venture called Elysis) to help expedite deployment of a new carbon-free process to extract pure aluminum from its ore.[13] For 130 years, carbon anodes have been used in the smelting process, which release carbon dioxide and other greenhouse gas emissions. The new process, expected to be commercialized by 2024, relies on patented ceramic anodes, which release no carbon into the atmosphere.[14]

Shifting from basic oxygen blast furnaces to electric arc furnaces in the production of iron-ore steel contributed to a 37 percent reduction in the energy intensity of U.S. crude steel production from 1991–2010.[15] The share of electric arc furnaces is expected to continue to increase through mid-century (though penetration levels are already north of 60 percent) which should help reduce energy consumption from this sub-sector. Additionally, recycling more product (as with other metals) will also reduce energy requirements. And companies like LanzaTech are capturing carbon monoxide from steel (working with ArcelorMittal) and other industrial facilities and converting them into ethanol, jet fuel, and other building blocks for plastics, reducing emissions and demand for fossil fuels.[16]

Dow Dupont and BASF developed a more environmentally friendly pathway to produce propylene oxide that creates less waste and uses less water and energy.[17] Propylene oxide is among the 30 largest volume bulk chemicals, and a raw material for many products including detergents, polyurethanes, de-icers, food additives, and personal care items.[18]

In some cases, switching inputs or raw materials can reduce emissions—for instance, using fly ash from coal-fired power plants instead of carbon-intensive clinker in cement production. Additionally, Lafarge Holcim and Solidia are working to commercialize low-carbon precast concrete that uses lower quantities of limestone and absorbs carbon dioxide in the curing process, which can reduce emissions up to 70 percent.[19], [20]

Additionally, in the bulk chemicals sub-sector, which includes plastics, fertilizers, cosmetics and detergents among other things, carbon-free ammonia (i.e., a fertilizer) may be coming soon. The U.S. Department of Energy is supporting a demonstration project in Indiana that is expected to be operational in 2022, capable of sequestering 1.75 million tons of carbon dioxide a year.[21] Some see greater potential in energy-dense ammonia, as a multipurpose fuel source, not unlike hydrogen.[22] Many are looking at more environmentally-friendly ways (i.e., they would not generate carbon dioxide) to synthesize ammonia at commercial scale using clean energy sources.[23]

Policies for Decarbonizing Industry

Federal support is needed to accelerate the efforts of companies and develop new emission reduction pathways. It is our strong view that economy-wide carbon pricing (e.g., carbon tax, cap-and-trade program or tradable performance standards) can drive private capital to facilitate significant emission reductions across the industrial sector, but a wide range of complementary policies are also needed. Priorities over the next decade include developing innovative lower-carbon manufacturing processes, using benchmarking to drive energy efficiency and fuel switching, and safeguarding the competitiveness of energy-intensive, trade-exposed sectors.

Advancing Low-Carbon Technologies

Leadership is necessary to rapidly advance a wide range of technologies to reduce or capture emissions from industrial processes and energy use. The federal government should support the research, development and demonstration of critical technologies, stronger public-private partnerships, and fast-track commercialization efforts.

As noted, the largest source of industrial energy demand is heat for industrial processes. Advanced nuclear designs, particularly molten salt reactors, offer a clean alternative for some high-temperature heating needs. Renewable heat sources including renewable natural gas (e.g., from agriculture, wastewater treatment and landfills), solar thermal, and geothermal also hold significant promise. Congress should significantly increase funding to develop and commercialize alternative thermal heat technologies including renewables and advanced nuclear producing combined heat and power. Companies like Cargill, GM, Kimberly-Clark, L’Oreal, Mars, P&G, and Stoneyfield, are working with C2ES and other NGOs to scale up renewable heating and cooling at their facilities as part of the Renewable Thermal Collaborative.[24]

In addition to emissions from energy use, industrial processes themselves produce significant levels of emissions in subsectors such as cement, steel and bulk chemicals. Congress should increase funding to research and develop innovative industrial processes with smaller carbon footprints. Even with such advances, and with reductions in energy-related emissions, significant levels of emissions will likely remain. Capturing those emissions for storage or utilization will be an essential strategy for decarbonizing the industrial sector. It is critical that Congress increase support for the development and deployment of carbon capture technologies.

Setting Industrial Benchmarks

To orient companies toward decarbonization, the federal government should undertake a benchmarking process to establish greenhouse gas objectives for the major sub-industries. This can be informed by programs already implemented in Canada and Europe. The benchmarking process will highlight best practices and promote industry-wide learning; the intensity-based benchmarks will provide ongoing goals for companies as they pursue their most cost-effective decarbonization options. These benchmarks can also be used to establish companies’ or facilities’ obligations under an economy-wide carbon pricing program, and to inform measures to address potential competitiveness concerns.

Providing Incentives

To drive the deployment of existing and emerging technologies and help companies reduce emissions, government should provide targeted incentives for efficiency, fuel switching and carbon capture, including:

- Federal, state, and local governments should support the deployment of conventional combined heat and power systems.

- Congress should extend and increase the existing 45Q tax credit for CCUS technologies to support the capture of process and on-site energy-related emissions, and should provide tax credits for energy efficiency improvements.

- To promote electrification and reduce dependence on fossil fuels, federal and state incentives should be offered for the adoption of electric boilers for industrial heat and other electrification measures (e.g., industrial heat pumps).

- CO2 infrastructure – pipelines, develop regional industrial hubs and infrastructure plans.

DOE has an important role in helping the private sector better understand the opportunities for clean energy and systems efficiency. Congress should expand funding for manufacturing initiatives through DOE’s Advanced Manufacturing Office, which should champion a circular economy approach (i.e., recycling) and seek decarbonization opportunities in advanced manufacturing, digitization and automation.

Federal, state, and local agencies procure significant quantities of materials for infrastructure projects, operations and other purposes. As a further incentive to industry to produce lower-emission goods, the federal government should institute “clean procurement” criteria that favor products with the lowest carbon intensity on a full lifecycle basis wherever possible. This requires establishing methodologies and criteria to evaluate a product’s embedded carbon.

Industrial Competitiveness

For subsectors that are energy-intensive and trade-exposed – i.e., their products are traded globally – the costs of decarbonizing may pose a potential competitive disadvantage. There may also be a risk that production will move to countries where greenhouse gas policies are not yet as stringent, resulting in “carbon leakage.” To date, all existing carbon pricing programs globally include specific provisions aimed at minimizing competitiveness and carbon leakage risks. An economy-wide carbon pricing program should include such provisions (e.g., free allocation of allowances in a cap-and-trade system, offering tax credits, rebates, border adjustments based on best in class benchmarks or other exemptions), all of which should be reexamined periodically.

Past and ongoing C2ES research suggests that potential competitive risks can be managed and should not be an obstacle to strong climate change policy. This conclusion is supported by a new analysis undertaken by C2ES on behalf of the World Bank, which will be released on September 21.

Closing Key Points

Given its tremendous diversity, its heavy reliance on large quantities of thermal heat, and the fundamental nature of many core manufacturing process, the industrial sector is especially challenging to decarbonize. It is our strong view that economy-wide carbon pricing can drive private capital to facilitate significant emission reductions across the industrial sector, but as we outlined above, a wide range of complementary policies are also needed. The large number of actions by companies, some of which were highlighted, shows that U.S. industry takes climate change seriously, desires transparent policy actions, can continue to be a global leader, as well as maintain its competitiveness.[25]

The federal government has a critical role to play. By enacting economy-wide carbon pricing and complementary policies, Congress will send an essential signal to companies, spur investment, and help accelerate the actions necessary to deeply decarbonize the industrial sector and help stave off the worst effects of climate change. So that by mid-century, a modernized U.S. industrial sector will continue to create jobs, growth and exports with a carbon neutral footprint.

[1] Center for Climate and Energy Solutions, “Climate Innovation 2050”, https://www.c2es.org/our-work/climate-innovation-2050/

[2] U.S. Environmental Protection Agency, “Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2017”, April 2019, https://www.epa.gov/sites/production/files/2019-04/documents/us-ghg-inventory-2019-main-text.pdf.

[3] “From Risk to Return: Investing in a Clean Energy Economy,” Risky Business Project, 2016, https://riskybusiness.org/fromrisktoreturn/.

[4] From the Reference Case of the AEO 2019, which assumes current policies only. U.S. Energy Information Administration, “Annual Energy Outlook 2019”, January 2019, https://www.eia.gov/outlooks/aeo/.

[5] Industrial sector emissions rose in 2018 by 13 MMtCO2 or 1 percent.

[6] Carbon Capture & Sequestration Technologies @MIT, “Non-Power Plant Carbon Dioxide Capture and Storage Projects,” September 30, 2016, http://sequestration.mit.edu/tools/projects/storage_only.html.

[7] U.S. Environmental Protection Agency, “CHP Benefits,” Accessed on May 22, 2019, https://www.epa.gov/chp/chp-benefits.

[8] U.S. Department of Energy, “Combined Heat and Power (CHP) Technical Potential in the United States”, March 2016, https://www.energy.gov/sites/prod/files/2016/04/f30/CHP%20Technical%20Potential%20Study%203-31-2016%20Final.pdf

[9] U.S. Department of Energy, “More than 550 Megawatts of New Combined Heat and Power Capacity Added in United States, Puerto Rico, and Virgin Islands”, August 2018, https://www.energy.gov/eere/amo/articles/more-550-megawatts-new-combined-heat-and-power-capacity-added-united-states-puerto

[10] For reference, the total installed capacity of all electric generation resources is around 1,100 GW.

[11] Net Power, “Net Power has Reinvented the Power Plant,” Accessed on May 22, 2019, https://www.netpower.com/technology/.

[12] Williams, J.H., B. Haley, F. Kahrl, J. Moore, A.D. Jones, M.S. Torn, H. McJeon (2014). Pathways to deep decarbonization in the United States. The U.S. report of the Deep Decarbonization Pathways Project of the Sustainable Development Solutions Network and the Institute for Sustainable Development and International Relations. Revision with technical supplement, Nov 16, 2015.

[13] Apple Newsroom, “Apple paves the way for breakthrough carbon-free aluminum smelting method,” accessed on May 22, 2019, https://www.apple.com/newsroom/2018/05/apple-paves-the-way-for-breakthrough-carbon-free-aluminum-smelting-method/.

[14] Melanie Burton, “Rio Tinto talking to Apple on next step of carbon-free aluminum project,” Reuters, March 8, 2019, https://www.reuters.com/article/us-australia-rio-tinto-bauxite/rio-tinto-talking-to-apple-on-next-step-of-carbon-free-aluminum-project-idUSKCN1QP1ED.

[15] Kelly Perl, “Changes in steel production reduce energy intensity,” Today in Energy, July 29, 2016, https://www.eia.gov/todayinenergy/detail.php?id=27292.

[16] LanzaTech, “About”, Accessed on September 12, 2019, https://www.lanzatech.com/.

[17] U.S. Environmental Protection Agency, “Presidential Green Chemistry Challenge: 2010 Greener Synthetic Pathways Award: The Dow Chemical Company, BASF”, Accessed on September 12, 2019, https://www.epa.gov/greenchemistry/presidential-green-chemistry-challenge-2010-greener-synthetic-pathways-award.

[18] Ibid.

[19] Lafarge Holcim Press Release, “Lafarge and Solidia commercialize a new low-carbon solution for the construction sector,” April 28, 2015, https://www.lafargeholcim.com/04282015-Lafarge-Solidia-commercialize-new-low-carbon-solution-for-construction-sector.

[20] Akshat Rathi, “The material that built the modern world is also destroying it. Here’s a fix,” Quartz, December 6, 2017, https://qz.com/1123875/the-material-that-built-the-modern-world-is-also-destroying-it-heres-a-fix/.

[21] Jenny Mandel, “DOE backs ‘world’s first carbon-free ammonia’,” E&E News Energywire, May 21, 2019, https://www.eenews.net/energywire/2019/05/21/stories/1060369553.

[22] Robert F. Service, “Ammonia—a renewable fuel made from sun, air, and water—could power the globe without carbon,” Science, July 12, 2018, https://www.sciencemag.org/news/2018/07/ammonia-renewable-fuel-made-sun-air-and-water-could-power-globe-without-carbon.

[23] Ibid.

[24] Renewable Thermal Collaborative, “About”, https://www.renewablethermal.org/about/.

[25] A wide range of companies are acting on climate; many have adopted emission reductions goals. An increasing number of large investor-owned utilities have laid out plans to deeply decarbonize their generation portfolios by mid-century. Many large companies have set out goals to procure 100 percent carbon-free electricity for their operations. More than 60 percent of the 2016 Fortune 100 have set targets to reduce greenhouse gas emissions, improve energy efficiency, and/or increase the use of renewables (WWF, Calvert Investments, CDP and Ceres, “Power Forward 3.0: How the largest US companies are capturing business value while addressing climate change”, April 2017, https://www.worldwildlife.org/publications/power-forward-3-0-how-the-largest-us-companies-are-capturing-business-value-while-addressing-climate-change). Additionally, companies are employing internal carbon pricing to systematically incorporate climate-related costs into investment and operational decisions and to incentivize least-cost reductions. And, they are working with employees, suppliers and major customers to promote carbon reduction throughout the value chain.