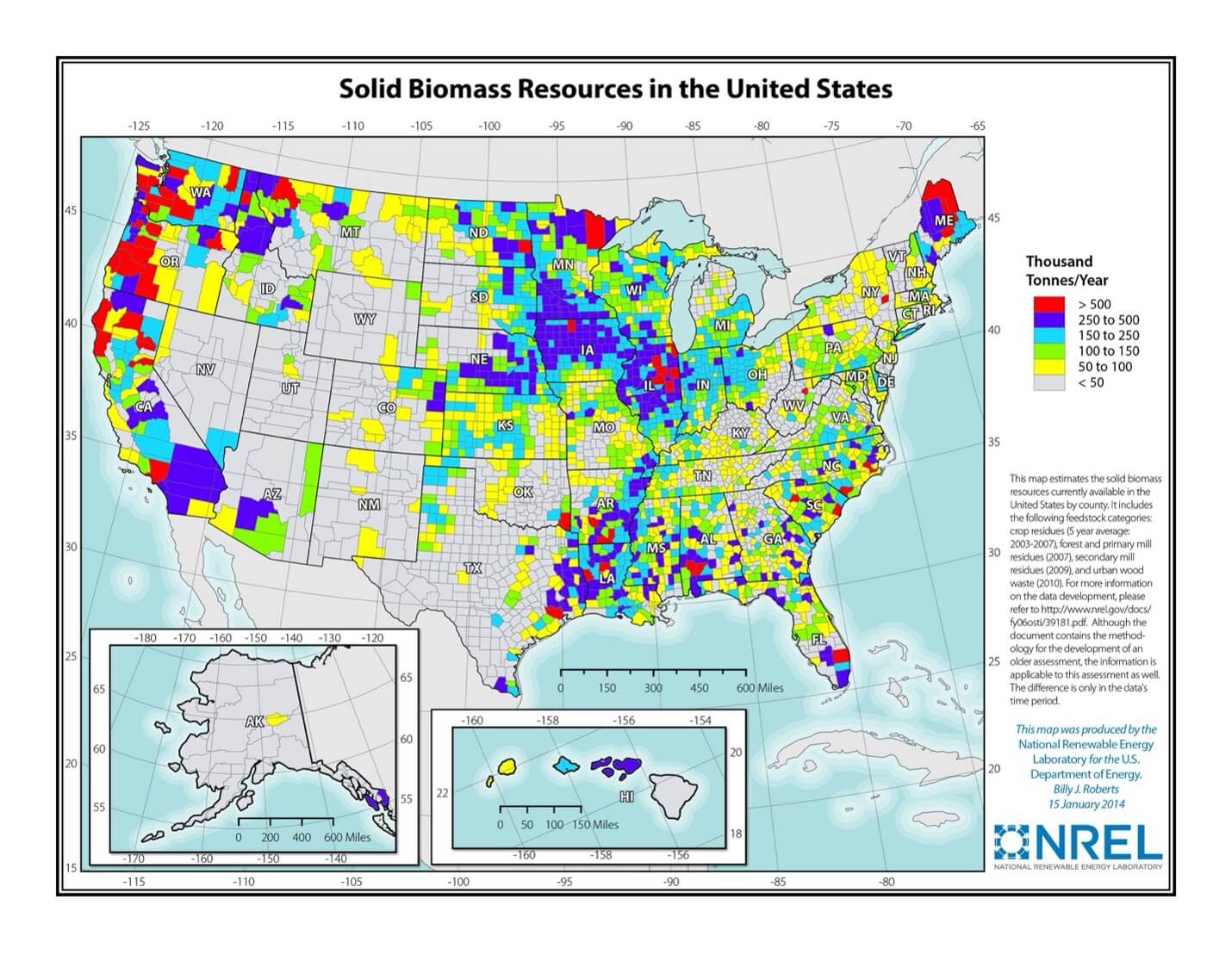

Biomass

Biomass energy sources are used to generate electricity and provide direct heating and can be converted into biofuels as a direct substitute for fossil fuels used in transportation. Unlike intermittent wind and solar energy, biomass can be used continuously or according to a schedule. Biomass is derived from wood, waste, landfill gas, crops, and alcohol fuels. Traditional biomass, including waste wood, charcoal, and manure, has been a source of energy for domestic cooking and heating throughout human history. In rural areas of the developing world, it remains the dominant fuel source. Globally in 2022, bioenergy accounted for about 5.8 percent of total final energy consumption. The growing use of biomass has resulted in increasing international trade in biomass fuels in recent years; wood pellets, biodiesel, and ethanol are the main fuels traded internationally.

In 2024, global biomass electric power capacity stood at 150.8 GW, increasing 3 percent from the previous year, the slowest rate in the last decade. The United States had 13 GW of installed biomass-fueled electric generation capacity. In the United States, most of the electricity from wood biomass is generated at lumber and paper mills using their own wood waste; in addition, wood waste is used to generate the heat for drying wood products and other manufacturing processes. Biomass waste is mostly municipal solid waste, i.e., garbage, which is burned as a fuel to run power plants. On average, a ton of garbage generates 550 to 750 kWh of electricity. Landfill gas contains methane that can be captured, processed and used to fuel power plants, manufacturing facilities, vehicles and homes. In the United States, there is currently around 1.7 GW of installed landfill gas-fired generation capacity across more than 500 projects.

In addition to landfill gas, biofuels can be synthesized from dedicated crops, trees and grasses, agricultural waste, and algae feedstock; these include renewable forms of diesel, ethanol, butanol, methane, and other hydrocarbons. Corn ethanol is the most widely used biofuel in the United States. Roughly 38 percent of the U.S. corn crop was diverted to the production of ethanol for gasoline in 2023, up from 20 percent in 2006. Gasoline with up to 10 percent ethanol (E10) can be used in most vehicles without further modification, while special flexible fuel vehicles can use a gasoline-ethanol blend that has up to 85 percent ethanol (E85).

Closed-loop biomass, where power is generated using feedstocks grown specifically for the purpose of energy production, is generally considered to be carbon dioxide neutral because the carbon dioxide emitted during combustion of the fuel was previously captured during the growth of the feedstock. While biomass can avoid the use of fossil fuels, the net effect of biopower and biofuels on greenhouse gas emissions will depend on full lifecycle emissions for the biomass source, how it is used, and indirect land-use effects. Overall, however, biomass energy can have varying impacts on the environment. Wood biomass, for example, contains sulfur and nitrogen, which yield air pollutants sulfur dioxide and nitrogen oxides, though in much lower quantities than coal combustion.

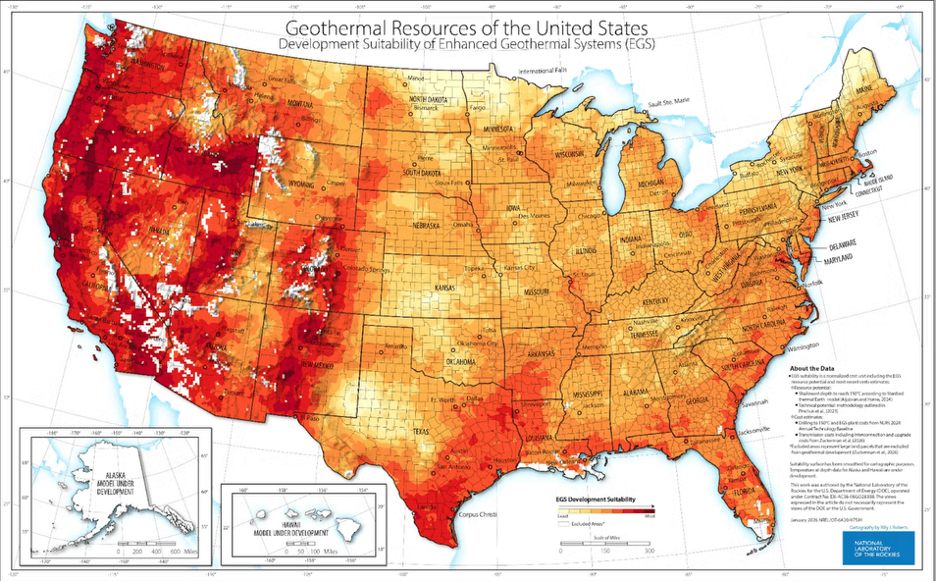

Geothermal

Geothermal provided an estimated 344 TWh globally in 2024, with 99 TWh in the form of electricity (with an estimated 15.1 GW of capacity) and the remaining half in the form of heat. (Total global electricity generation in 2024 was over 30,000 TWh).

In the United States, nearly 16 TWh of geothermal electricity was generated in 2024, making up about 0.4 percent of total electricity generation. Seven states generated electricity from geothermal energy: California, Hawaii, Idaho, Nevada, New Mexico, Oregon and Utah. Of these, California accounted for two-thirds of this generation.

Traditional geothermal energy exploits naturally occurring underground heat, water and permeability, located relatively close to the Earth’s surface in some areas, to generate electric power and for direct uses such as heating and cooking. Geothermal areas are generally located near tectonic plate boundaries, where there are earthquakes and volcanoes. In some places, hot springs and geysers have been used for bathing, cooking and heating for centuries

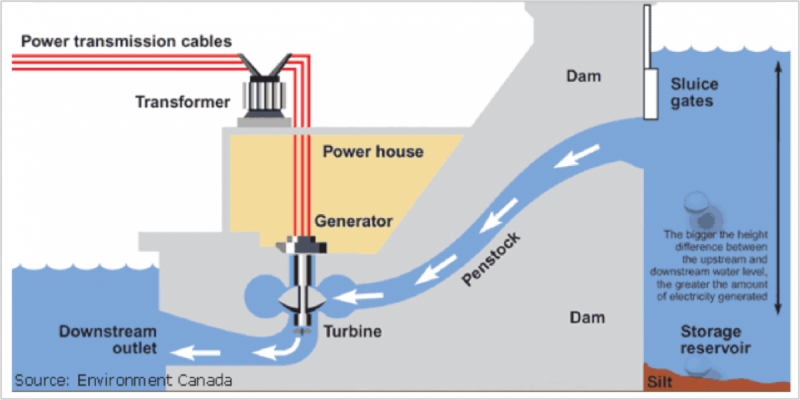

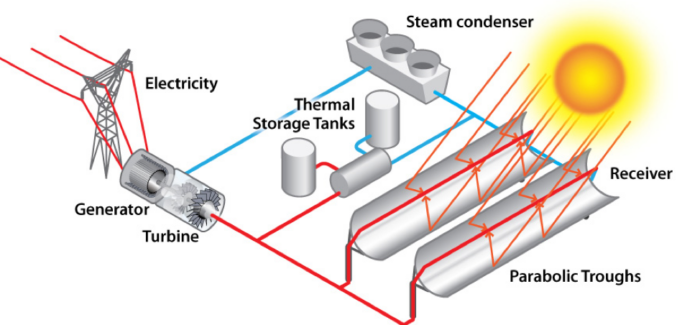

Generating geothermal electric power typically involves drilling a well, perhaps a mile or two in depth, in search of rock temperatures in the range of 300 to 700°F. Water is pumped down this well, where it is reheated by hot rocks. It travels through natural fissures and rises up a second well as steam, which can be used to spin a turbine and generate electricity or be used for heating or other purposes. Several wells may have to be drilled before a suitable one is in place and the size of the resource cannot be confirmed until after drilling. Additionally, some water is lost to evaporation in this process, so new water is added to maintain the continuous flow of steam. Like biopower and unlike intermittent wind and solar power, geothermal electricity can be used continuously. Very small quantities of carbon dioxide trapped below the Earth’s surface are released during this process.